By Nick Carey and Christina Amann

LONDON/BERLIN (Reuters) -Global automakers are scouring the globe for crucial rare earths ahead of looming Chinese export controls, with executives worried they could lead to parts shortages and plant closures.

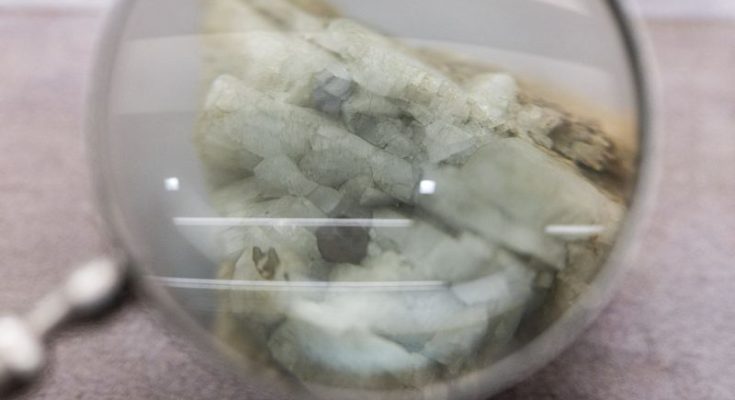

Rare earth magnets power motors in car parts such as side mirrors, speakers, oil pumps, windshield wipers and fuel leakage and braking sensors. They play an even bigger role in EVs.

While a U.S.-China deal diverted a supply threat, stockpiles were depleted by similar restrictions earlier this year, while Beijing has also made it harder to get export licenses.

China has since dramatically expanded export curbs, with companies facing global supply shortages.

Consultancy AlixPartners estimates China controls up to 70% of global rare-earths mining, 85% of refining capacity and about 90% of rare-earths metal alloy and magnet production.

The new Chinese export control list includes elements like ytterbium, holmium and europium, also used in making cars.

“The situation is very tense,” said Nadine Rajner, CEO of German metal-powder supplier NMD, adding customers want to source rare earths from anywhere but China.

As part of efforts to counter Chinese dominance, on Monday President Donald Trump and Australian Prime Minister Anthony signed a critical minerals agreement that includes U.S. investments in rare earth mining projects in Australia.

NMD’s Rajner said that while there are plenty of rare earths available in countries like Sweden, they do not have the mines or refining capacity to make them usable. And for heavy rare earths, China controls 99.8% of global refining capacity, making alternative sources negligible.

“We are pretty much sold out and have limited stocks,” Rajner said.

Rare earths can be recycled from old cars, but that industry is in its infancy. Neutral, a Renault-backed company, currently recycles rare earths from 400,000 cars a year in France and has contracts with 15 brands in Europe.

But “the challenge is scaling up these activities,” said Neutral CEO Jean-Philippe Bahuaud.

‘ALREADY BEEN DEPLETED’

Even if Chinese suppliers can fulfil fresh orders before the November 8 export controls take effect, the journey by sea to Europe can take 45 days and the threat of a rare earth bottleneck is among several headaches facing the auto industry.

China has also placed export restrictions on lithium-ion batteries and battery materials, triggering concerns over parts supplies for electric vehicles.

And last week, an intellectual-property dispute between China and the Netherlands involving little-known Dutch chip-maker Nexperia, sparked fears of factory closures because it supplies a large amount of chips car parts and components.